- The Factory Wire

- Posts

- Weekly 5: September 12, 2025

Weekly 5: September 12, 2025

The Factory Wire: Manufacturing Intel, Simplified

🏭 Top Story

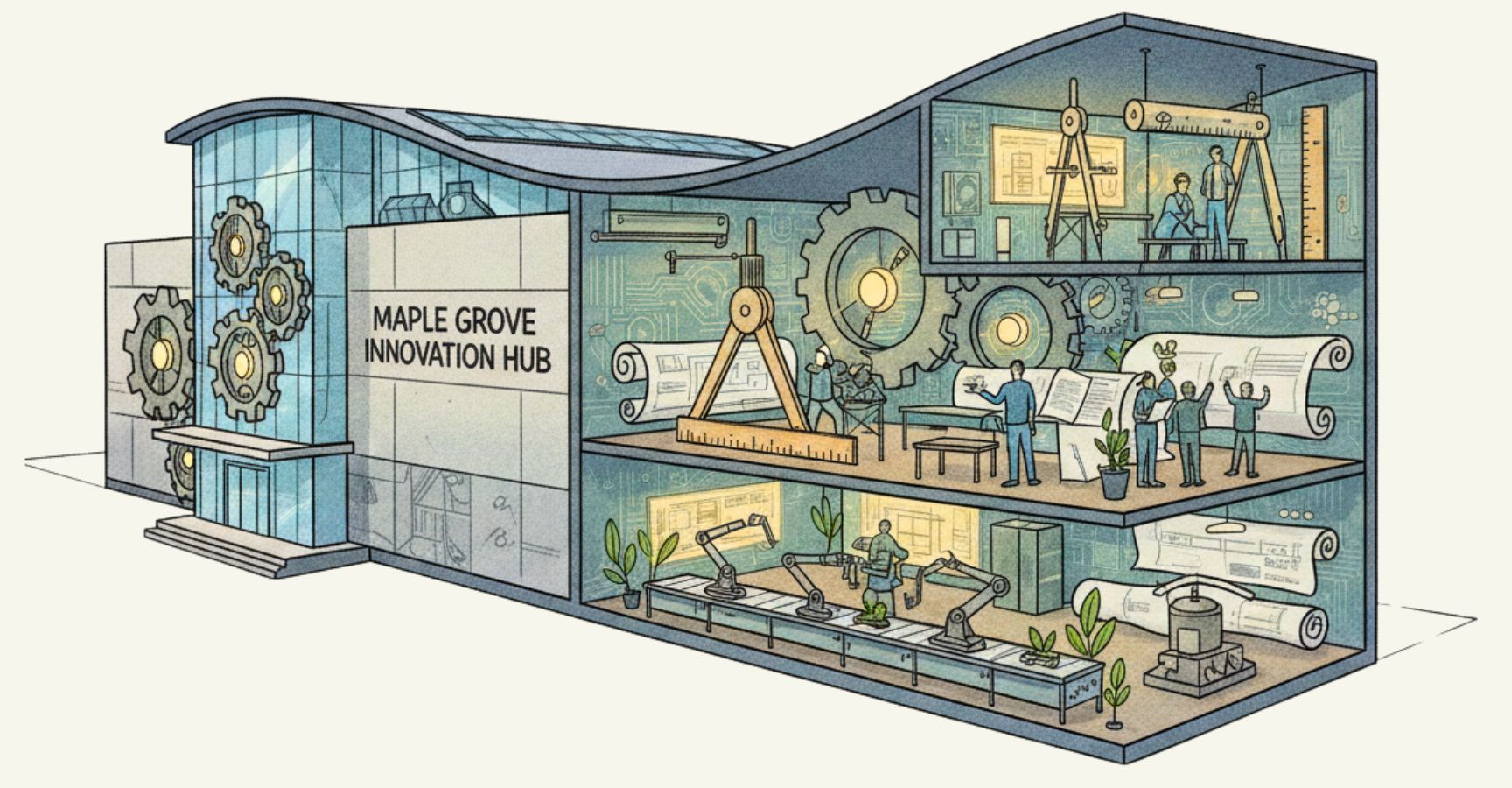

BAE Systems Opens State-of-the-Art Engineering Hub in Minnesota

BAE Systems has inaugurated a 247,000-square-foot engineering and product development facility in Maple Grove, Minnesota. The site features advanced labs for digital engineering, simulation, system integration, and prototyping. It will support the development of naval guns, munitions, submarine components, and combat vehicles for U.S. forces and allies.

This facility continues BAE’s 80-year legacy in Minnesota, reinforcing innovation and national defense capabilities.

📈 Market Snapshot

Insight: S&P 500 Industrials moved up 2.0% over the past week, reflecting positive sentiment in the manufacturing sector.

⚙️ Quick Takes

🤖 AI Powers Growth for Minnesota’s Small Businesses

Small manufacturers and service firms in Minnesota are using AI to overcome labor shortages, cut costs, and accelerate innovation. From data analysis to factory automation, AI is proving a game changer for profitability and growth.

Read the full story at StarTribune.com ➜

🏭 Can Big Investments Truly Revive U.S. Manufacturing?

Major firms like Apple and TSMC have pledged billions to expand U.S. manufacturing under the Trump administration. Yet, experts caution that tariffs and policy hurdles may limit the long-term impact of these high-profile investments.

Read the full story at ManufacturingDive.com ➜

🚚 Kodiak Robotics Rolls Out First Factory-Made Autonomous Truck

Kodiak Robotics, in partnership with Roush Industries, has delivered its first factory-upfitted autonomous truck to Atlas Energy Solutions. The milestone marks a step toward scaling production, with plans to reach hundreds of driverless trucks by 2026.

Read the full story at FreightWaves.net ➜

📲 Digitizing Manufacturing: Unlocking Efficiency with a Paper-on-Glass Strategy

Shifting from paper-based records to digital “paper-on-glass” workflows helps manufacturers cut errors, boost traceability, and streamline compliance. With the right infrastructure, integration, and user adoption, this approach lays the foundation for smarter, scalable, and more sustainable operations.

Read the full story at PlantEngineering.net ➜

📊 This Week's Chart

Insight: Capacity utilization remained stable to 76.8%, indicating moderate factory utilization rates and balanced operations.

📬 Share The Factory Wire

The Factory Wire delivers the week's most important manufacturing news and insights directly to industry decision-makers. Forward this newsletter to colleagues who need to stay informed about manufacturing trends: TheFactoryWire.com

Follow us on, LinkedIn → @TheFactoryWire

See you next week,